Corn Testing Process at the Dale Feed Mill

Oct 09, 2020

Megan Hasenour | Marketing Communications Manager

Corn is the main ingredient in most of our livestock nutrition formulations. The feed mill receives local corn from our member-customers. Quality management is very important at our Dale Feed Mill and key to ensuring that the corn we receive meets testing requirements. The purpose of the testing is to ensure that the corn is within the appropriate levels to prevent contamination.

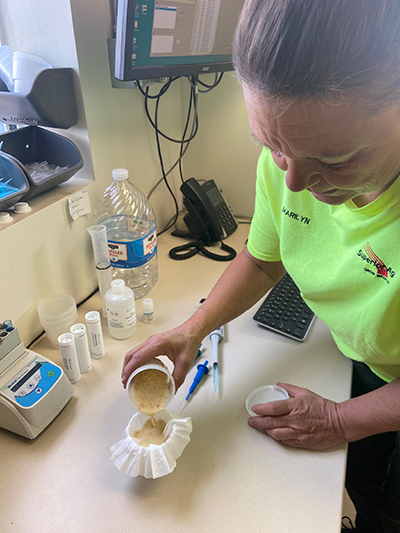

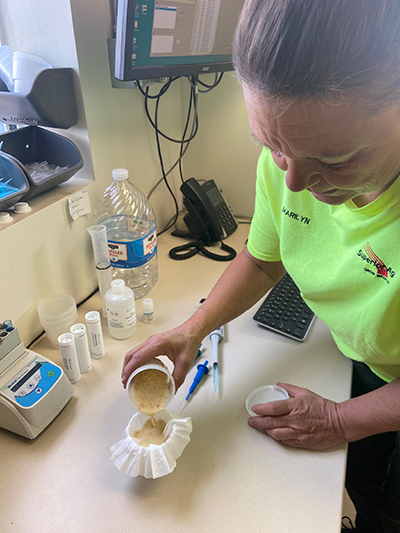

Superior Ag’s Lab Technician tests every single load of corn before it is unloaded at our Dale Feed Mill. We caught up with our Lab Technician, Marilyn Leonard, and she explained the corn testing process.

The corn sample is moisture tested and will only be accepted if the moisture is under 15.5%.

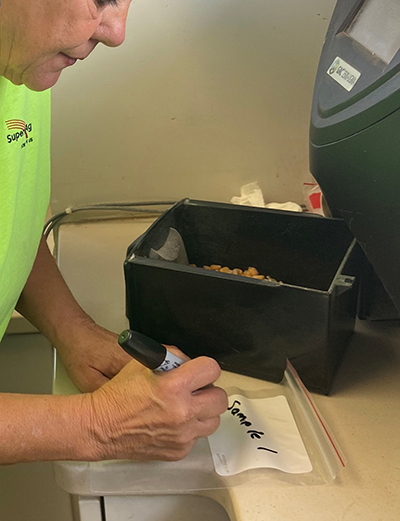

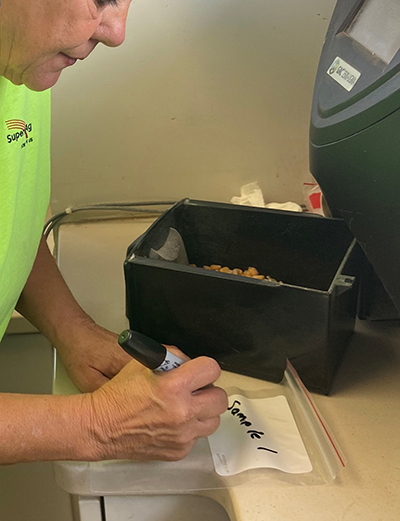

When the corn is under the moisture standards, a small amount of corn is kept with the customer’s name, date, sample number.

This sample of corn is kept on file for 6 months for traceability.

The remainder of the corn is ground into fine form through a state-of-the-art coffee grinder.

The ground corn is measured out to in a lab beaker (any remaining ground corn is discarded).

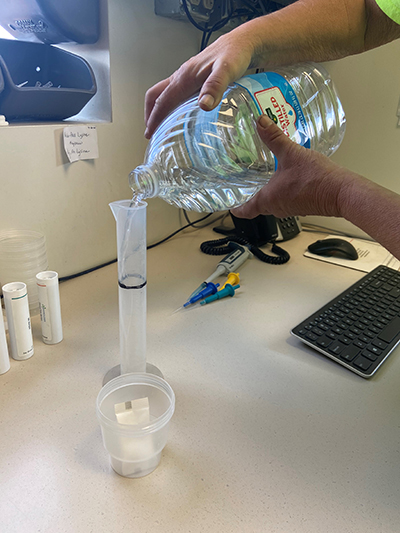

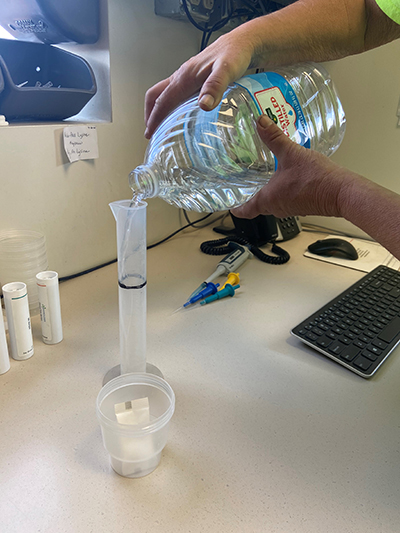

Extraction powder is added to distilled water in a collection cup, then shaken.

The ground corn sample is added to the collection cup.

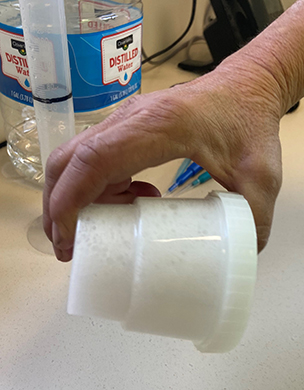

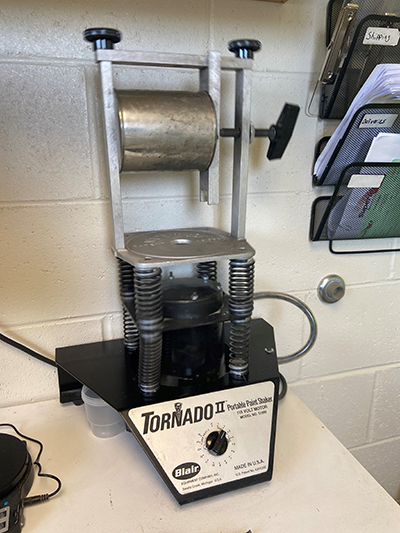

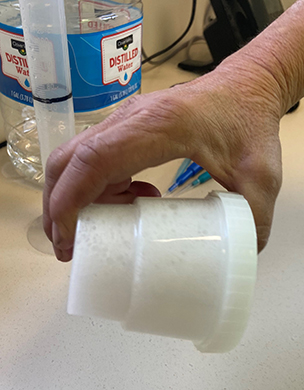

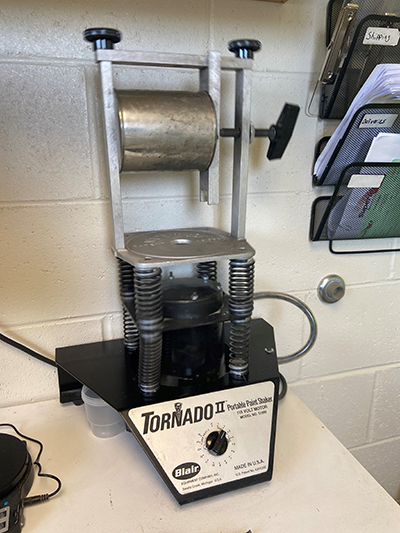

The collection cup with the solution of the extraction powder, distilled water and ground corn is tightly sealed and placed into a paint shaker. The solution is shaken vigorously for 30 seconds and then removed from the shaker to settle for 4 minutes.

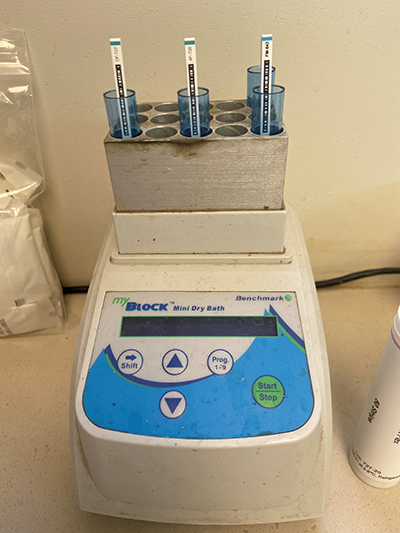

Dilution buffer is measured out with syringes and put into 3 test tubes for each of the 3 tests to be conducted.

A coffee filter is put on top of an empty collection cup. The corn solution is poured onto the filter and the liquid is filtered through.

After the liquid seeps, the coffee filter with the corn is discarded.

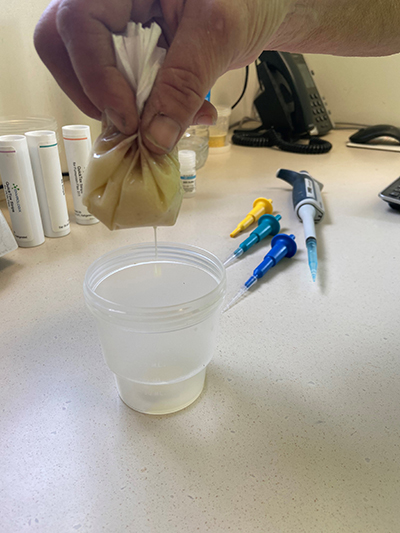

A syringe collects the filtered liquid and dispenses a certain amount of liquid into each of the 3 test tubes for testing to begin.

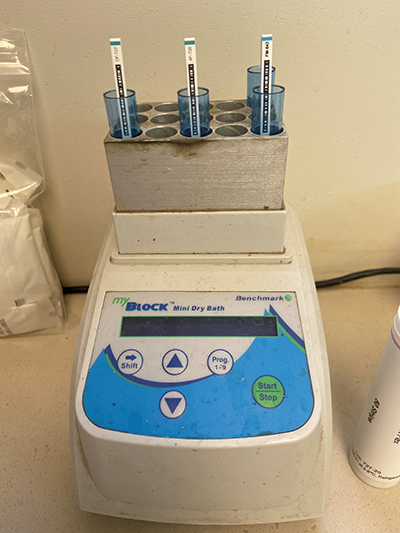

After the filtered liquid is added, testing strips are put into the test tubes.

The strips are required to sit in the incubator for 4 minutes.

We test for Aflatoxin, Fumonisin and DON. The test strips are removed from the test tubes, placed into a slide out drawer and put into a quick scan scanner to read the results.

The results appear on the computer screen and tell the Lab Technician if the corn passes the three tests.

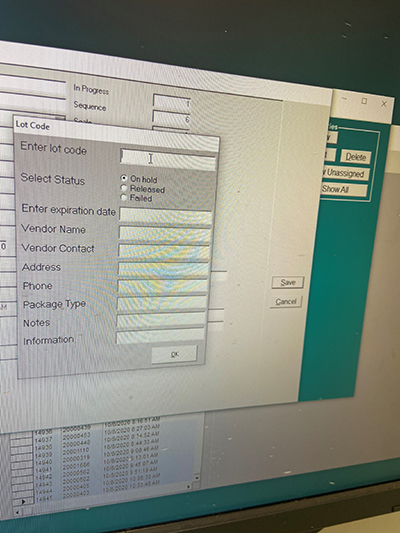

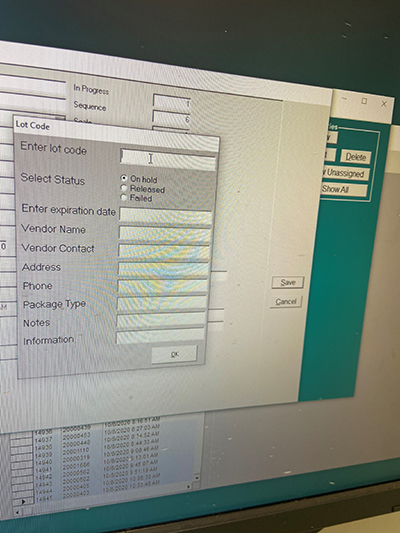

Each load of corn received is given a lot number for traceability purposes.

This entire process takes about 12 minutes. The driver of the corn truck does have to wait during this time, in order to ensure their the load of corn meets the requirements that the Feed Mill accepts.

The effects that Corn has when it contains too high of amounts of Aflatoxin, Fumonisin and DON is harmful to livestock. Having high levels of mycotoxins in corn can do the following to the swine species:

Essentially, mycotoxins such as: Aflatoxin, Fumonisin and DON are from Mold infection in the kernels.

There are a few ways to help manage mold infection on your operation. One way is to control insects, because insect damage makes corn much more susceptible to mold growth.

Here is a link with some valuable information included about Mycotoxins:

Iowa State University Extension - Mycotoxin Article

If you happen to have additional questions regarding mold reducing agronomic recommendations, contact your local Superior Ag Agronomist today! Superior Ag Agronomists - By Location

Corn is the main ingredient in most of our livestock nutrition formulations. The feed mill receives local corn from our member-customers. Quality management is very important at our Dale Feed Mill and key to ensuring that the corn we receive meets testing requirements. The purpose of the testing is to ensure that the corn is within the appropriate levels to prevent contamination.

How do we perform a test on corn to know it meets requirements?

Superior Ag’s Lab Technician tests every single load of corn before it is unloaded at our Dale Feed Mill. We caught up with our Lab Technician, Marilyn Leonard, and she explained the corn testing process.

Here’s the process:

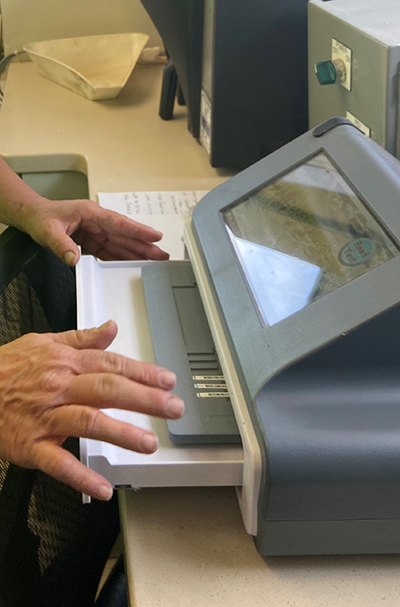

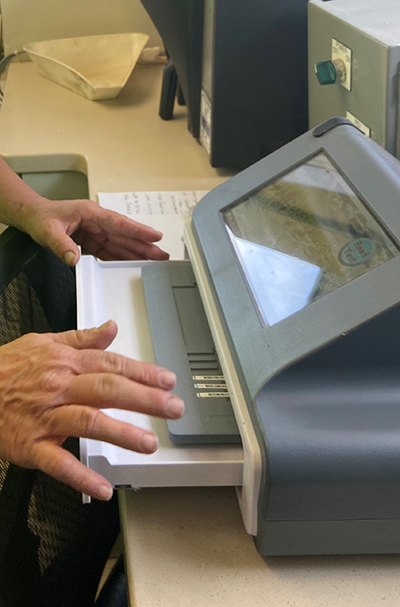

When a corn delivery truck comes to the feed mill, it is probed in about 3-6 different locations. This ensures we receive a representative sample throughout the truck. Our Lab Technician begins to test the corn sample.

The corn sample is moisture tested and will only be accepted if the moisture is under 15.5%.

When the corn is under the moisture standards, a small amount of corn is kept with the customer’s name, date, sample number.

This sample of corn is kept on file for 6 months for traceability.

The remainder of the corn is ground into fine form through a state-of-the-art coffee grinder.

The ground corn is measured out to in a lab beaker (any remaining ground corn is discarded).

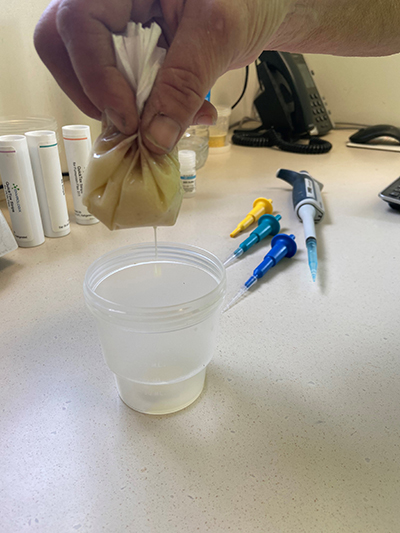

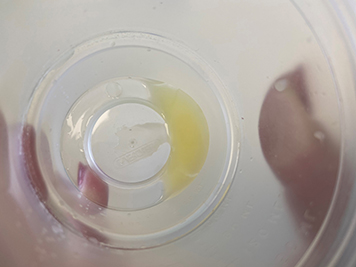

Extraction powder is added to distilled water in a collection cup, then shaken.

The ground corn sample is added to the collection cup.

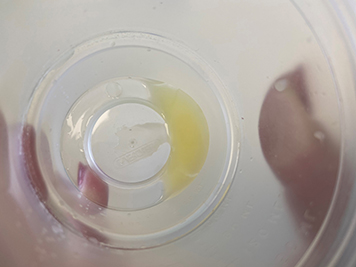

The collection cup with the solution of the extraction powder, distilled water and ground corn is tightly sealed and placed into a paint shaker. The solution is shaken vigorously for 30 seconds and then removed from the shaker to settle for 4 minutes.

Dilution buffer is measured out with syringes and put into 3 test tubes for each of the 3 tests to be conducted.

A coffee filter is put on top of an empty collection cup. The corn solution is poured onto the filter and the liquid is filtered through.

After the liquid seeps, the coffee filter with the corn is discarded.

A syringe collects the filtered liquid and dispenses a certain amount of liquid into each of the 3 test tubes for testing to begin.

After the filtered liquid is added, testing strips are put into the test tubes.

The strips are required to sit in the incubator for 4 minutes.

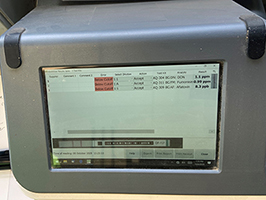

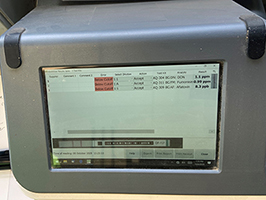

We test for Aflatoxin, Fumonisin and DON. The test strips are removed from the test tubes, placed into a slide out drawer and put into a quick scan scanner to read the results.

The results appear on the computer screen and tell the Lab Technician if the corn passes the three tests.

- Aflatoxin must be less than 20 parts per billion

- Fumonisin must be under 8 parts per million

- DON must be under 5 parts per million

If the test results are above these numbers, the entire load of corn is rejected, and the driver is unable to unload at the feed mill.

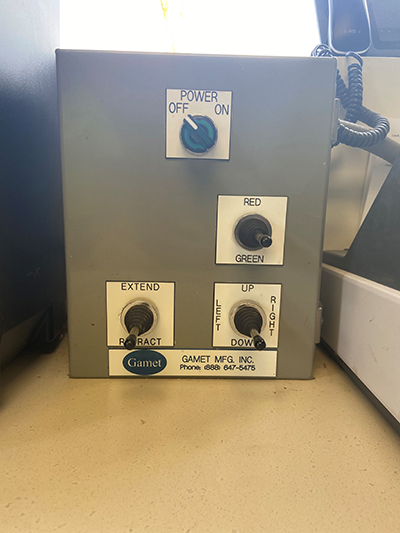

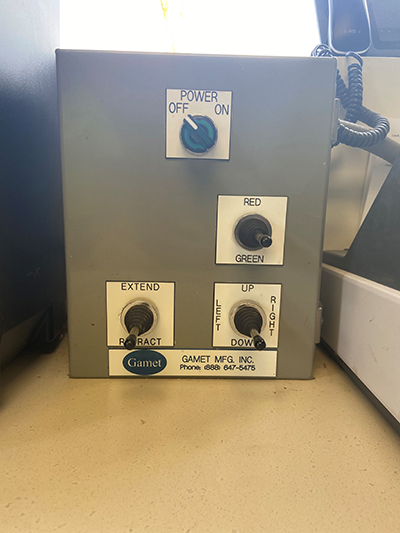

If the test results come back under these numbers, the truck is approved, scaled in and given the green light to proceed to the receiving pit to unload their load of corn.

Each load of corn received is given a lot number for traceability purposes.

This entire process takes about 12 minutes. The driver of the corn truck does have to wait during this time, in order to ensure their the load of corn meets the requirements that the Feed Mill accepts.

The effects that Corn has when it contains too high of amounts of Aflatoxin, Fumonisin and DON is harmful to livestock. Having high levels of mycotoxins in corn can do the following to the swine species:

- reduce feed intake

- reduce weight gain

- nausea

- diarrhea

- suppress of the immune system

- damage the kidneys

Essentially, mycotoxins such as: Aflatoxin, Fumonisin and DON are from Mold infection in the kernels.

There are a few ways to help manage mold infection on your operation. One way is to control insects, because insect damage makes corn much more susceptible to mold growth.

Here is a link with some valuable information included about Mycotoxins:

Iowa State University Extension - Mycotoxin Article

If you happen to have additional questions regarding mold reducing agronomic recommendations, contact your local Superior Ag Agronomist today! Superior Ag Agronomists - By Location